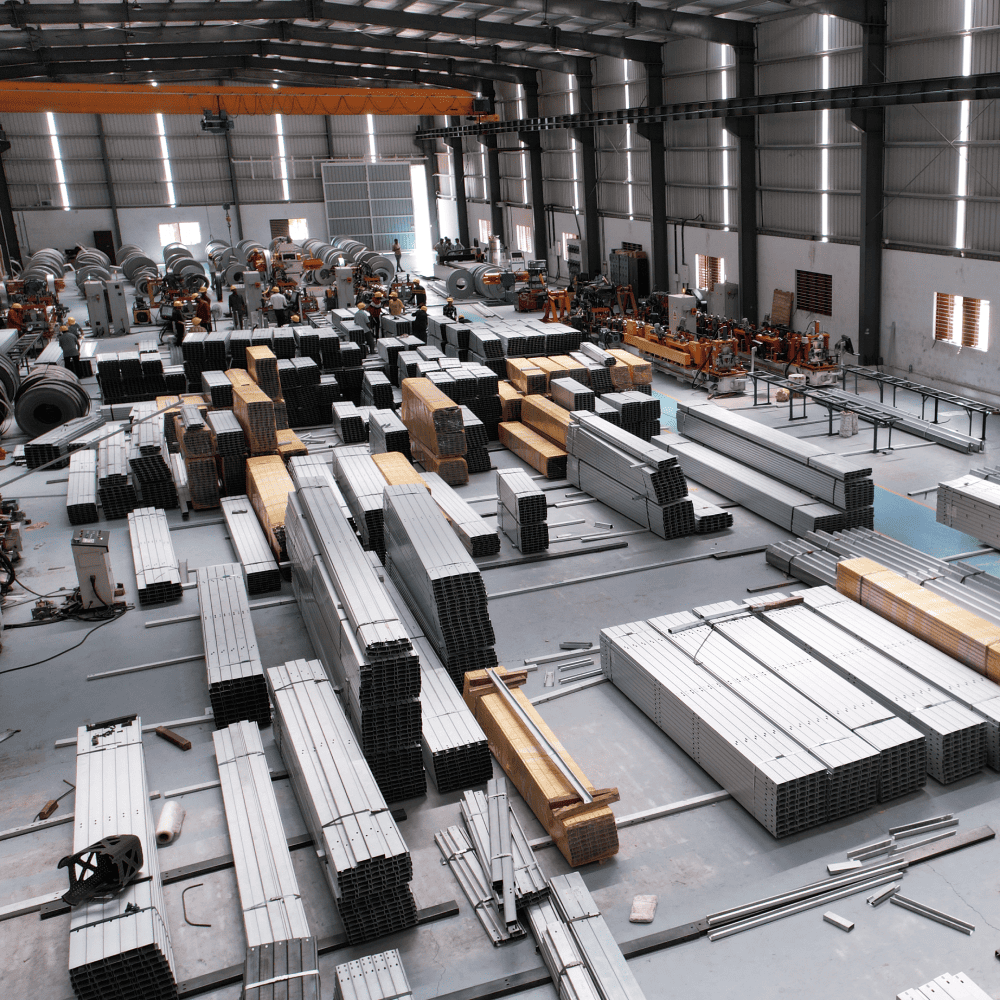

Hot-Dip Galvanizing

Hot-dip galvanizing is a process in which steel or iron is coated with a layer of zinc to protect it from corrosion. The steel or iron is submerged in a bath of molten zinc at a temperature of around 450°C (842°F). When the metal is removed from the bath, the zinc chemically bonds with the steel, creating a tough, durable layer that protects the underlying metal from rust and other forms of corrosion.

Hot-dip galvanizing provides excellent corrosion resistance and durability, making it ideal for harsh environments. The zinc coating is highly resistant to impacts and abrasions, ensuring protection for structures exposed to heavy wear and tear. Its metallurgical bond with steel is far stronger than conventional coatings, allowing it to withstand extreme conditions such as chemicals, saltwater, and industrial pollutants.

Our Service Benefits

-

Provides long-term corrosion resistance for extended lifespan.

Provides long-term corrosion resistance for extended lifespan.

-

Requires minimal upkeep, reducing overall maintenance costs.

Requires minimal upkeep, reducing overall maintenance costs.

-

Ensures complete protection, even in hard-to-reach areas.

Ensures complete protection, even in hard-to-reach areas.

-

Offers cathodic protection, safeguarding exposed steel from corrosion.

Offers cathodic protection, safeguarding exposed steel from corrosion.

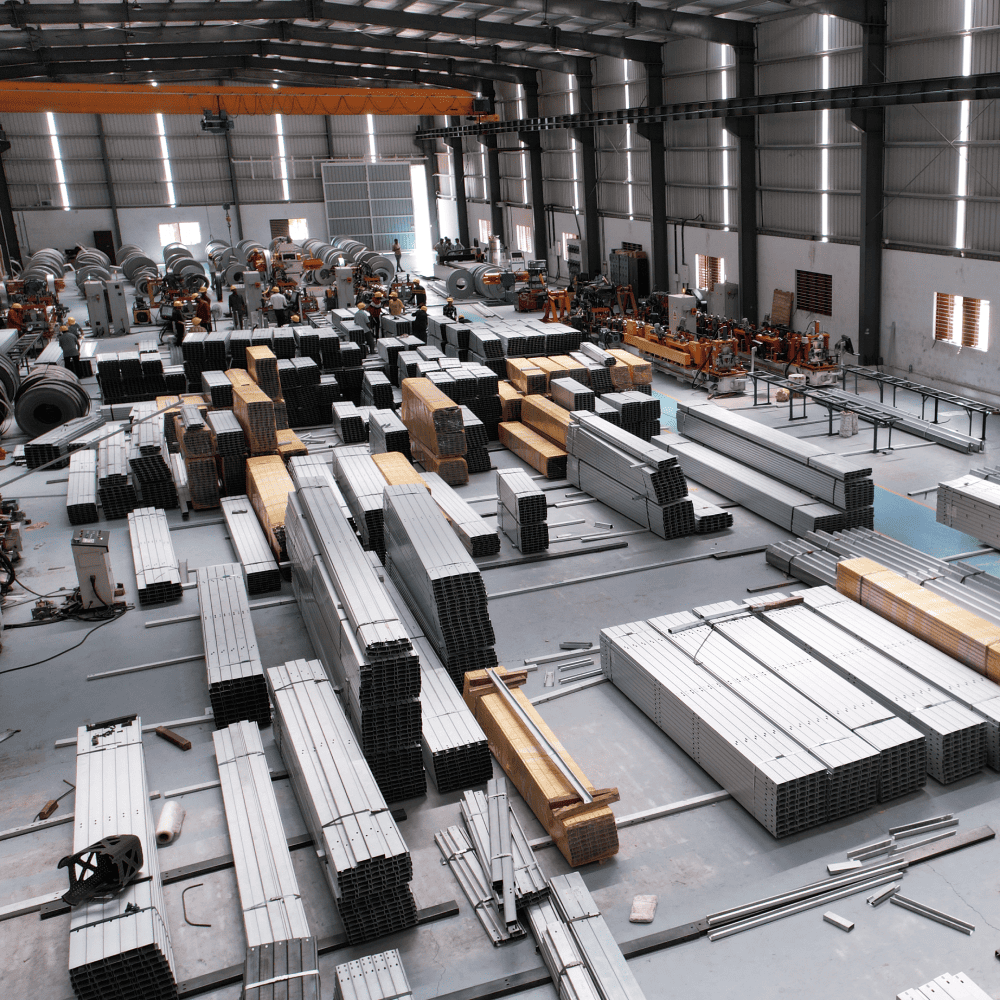

Our Latest Projects

Hot-Dip Galvanizing

Hot-Dip Galvanizing